Seasoned for added stability

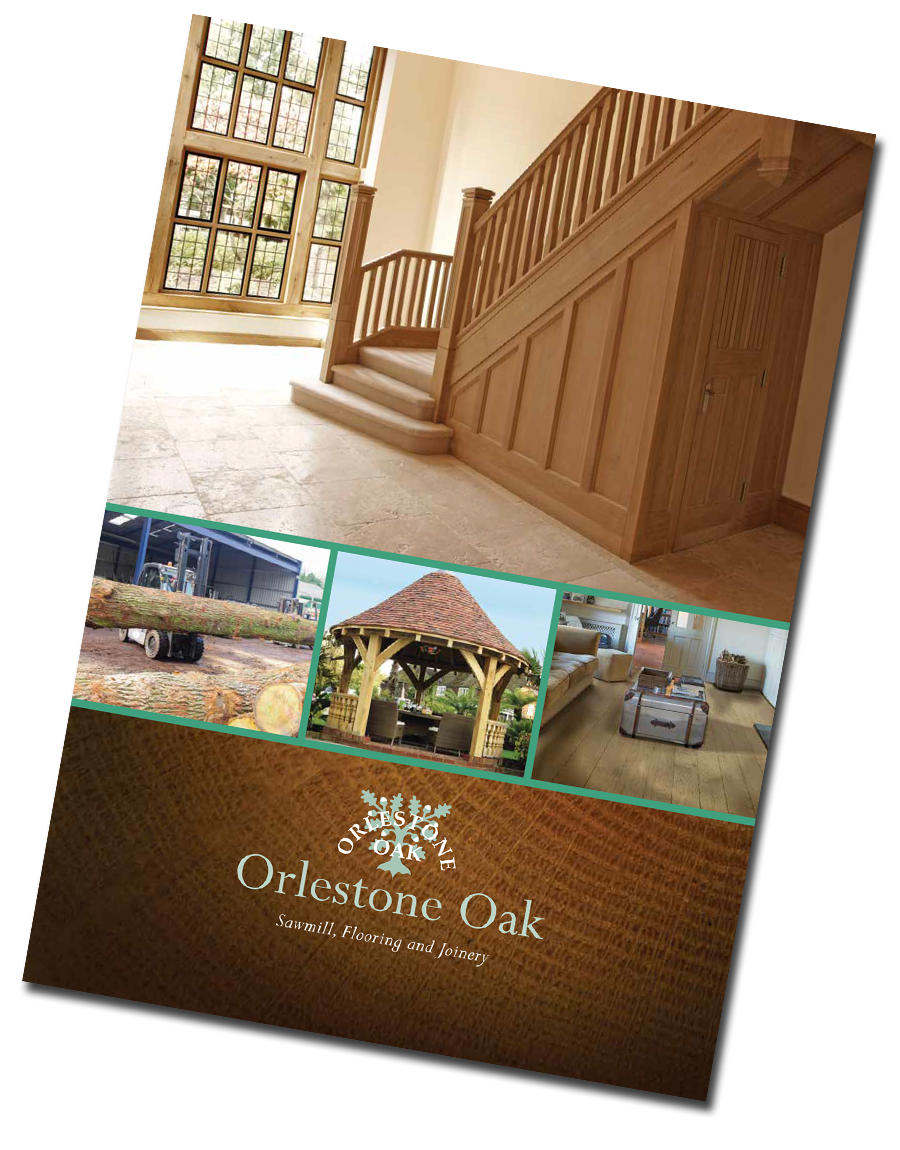

Orlestone oak has been supplying air-dried oak beams to Kent, Surrey and Sussex for over six decades. During this time we have gained a wealth of experience in supplying a high-quality product directly to both the public and trade customers.

The process of creating high-quality oak air-dried beams begins in our sawmill in the heart of Kent, we select and cut green oak with our own saw which is one of the largest of its kind in the country. Once the beams have been cut to size they will then be stored with oak battens between one another creating open airflow to thoroughly dry the beam. This part of the process can take up to several years and we ensure that no shortcuts are taken during this step as it’s a vital part of producing high-quality air oak-dried beams correctly.

As a natural products air dried oak beams go through multiple stages of movement as it’s exposed to the elements, which can result in a degree of cracks and splits. As part of our service to counter this and supply the best-air-dried oak beams, we can re-saw the beam to give a fresh square cut ready for use.

Typically green oak beams are used for construction, but there are certain cases where air dried is needed as green oak shrinks it can cause problems, floor joist is a common scenario for this.